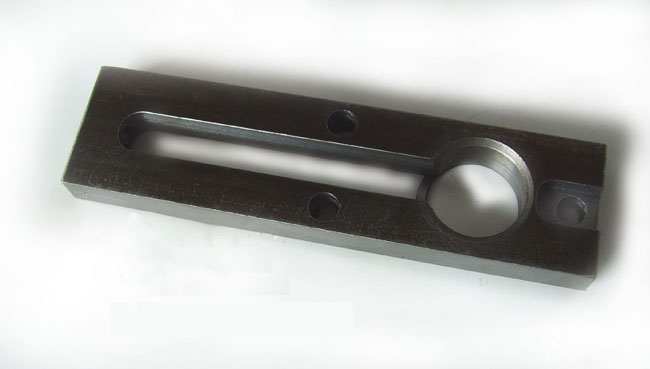

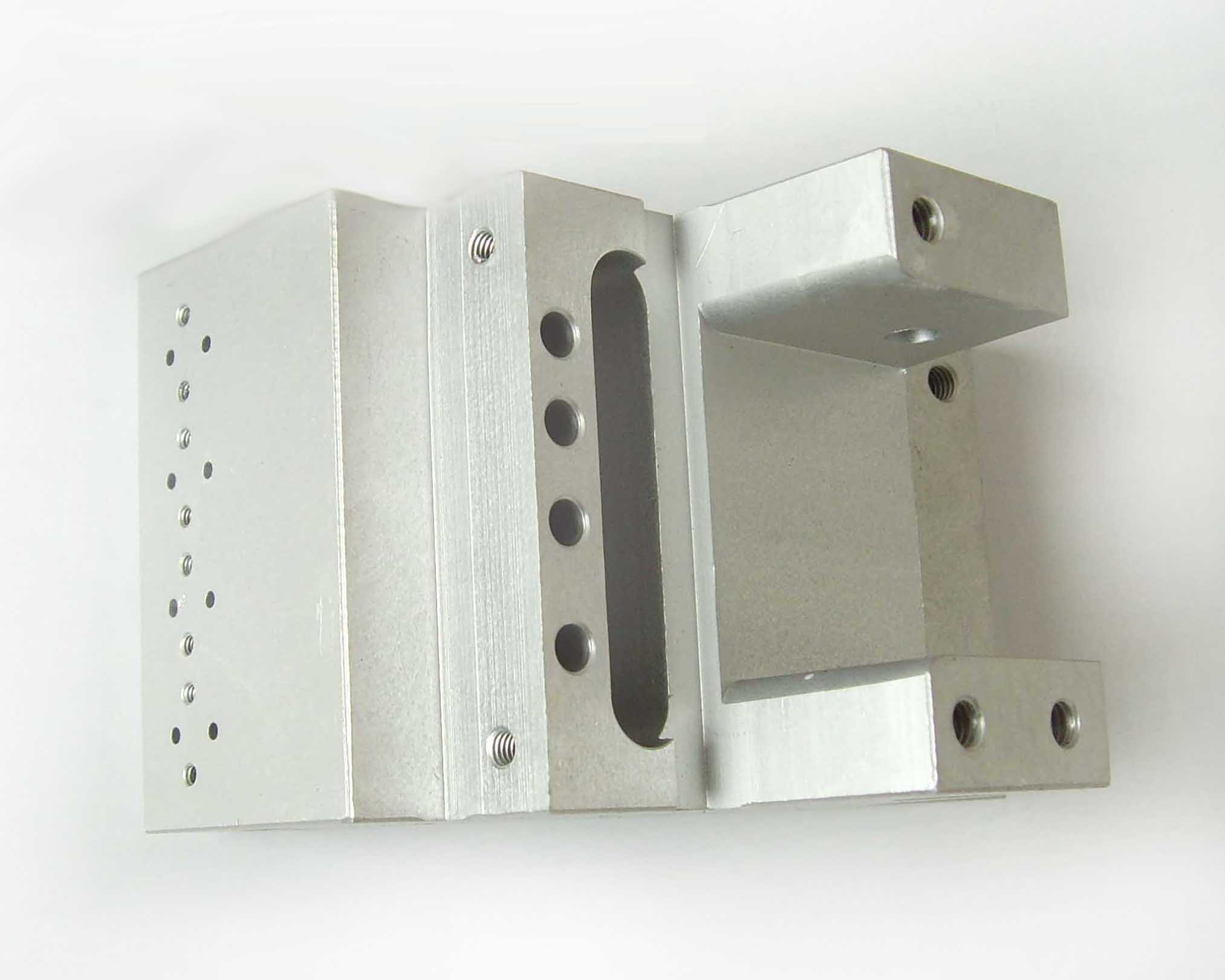

Mingzhi technology provide all kinds of machinery products and parts of the equipment. Our products range from small parts with a diameter of 1mm to a variety of large parts and the processing methods are also varied. The products are widely used in electronics, electricals, automobile, construction machinery and household appliances and so on.

We use CNC and NC to improve the production efficiency and precision and the materials can be processed are mainly iron, stainless steel, aluminum alloy and copper and so on. Materials like tungsten alloy and titanium alloy or PETT, PC, PE and other materials can also be processed here. To meet the diverse needs of customers is our first consideration and at the same time we also strive for quality improvement and technology promotion.

Other production tools, jig and fixture tooling and testing equipment also can be produced according to customers’ requirements.

From getting the drawings or CAD/CAM data, the time from getting placing an order to delivery can be greatly shortened through the network transmission.

Machining, heat treatment and surface treatment are indispensable. We have cooperated manufacturers to do professional surface treatment that can complete a variety of heat treatment with high quality.

Mingzhi company also has cooperated factories in welding. Automatic welding machines and skilled techniques can provide stable and high-quality products.

The types of welding are welding, TIG, CO2, spot welding and gas welding. We may use different welding methods according to the different purposes and requirements.

As TIG has stable property and generates less heat, it does not damage the products and the deformation is small, so it is suitable for thin plate and precision parts. It is commonly used in the welding of precision equipment and sealed tube. In addition, as there is no welding slag produced, it generally applies to highly polished products.

| Item | Metal |

| TIG | Steel |

| stainless steel | |

| GO2 | steel |

X does not only rely on the equipment, technology and experience is also very important. Based on our years of experience, we also pay great attention to the appearance of the products, removing the burr and keeping the surface clean and nice-looking.

Our company will inspect on the parts processed in accordance with the requirements and do packaging and shipment after they are deemed qualified. Detection equipment is also inspected on a regular basis to maintain the precision required.

A1001 |

A1002 |

A1003 |

A1004 |

A1005 |

A1006 |

A1007 |

B1008 |

B1009 |

B1010 |

B1011 |

B4001 |

B4002 |

B4003 |

B4005 |

C1013 |

C1014 |

C1015 |

C1016 |

D1057 |

M1049 |

M1050 |

M1051 |